Why can magnesium hydroxide be used as a common flame retardant?

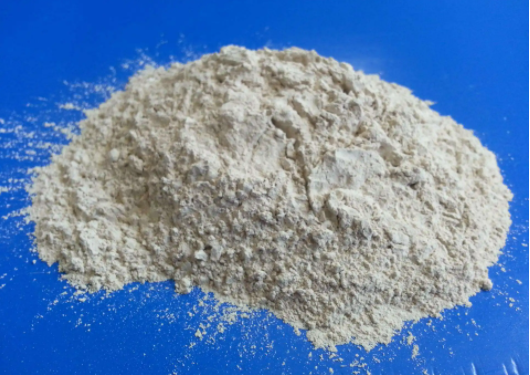

With the continuous improvement of living standards, people's requirements for the quality of life are getting higher and higher, and some polymers have entered our daily lives. However, these polymer materials have a problem during use, that is, flammability, which can easily lead to fire accidents. Therefore, we need to add flame retardants to these materials to prevent fires. General flame retardants include aluminum oxide, aluminum hydroxide, zinc oxide,Magnesium hydroxideAmong these commonly used flame retardants, magnesium hydroxide is widely used.

Why?Magnesium hydroxideCan be added to various polymer materials as a common flame retardant? This is because it decomposes during heating to release bound water to absorb a large amount of latent heat and reduce the surface temperature of the synthetic material filled in the flame. It can also suppress smoke. When a fire produces a large amount of smoke and heat conduction, people cannot escape from the scene. Magnesium hydroxide can solve this problem well and reduce the risk of suffocation by smoke. In addition to flame retardant, smoke suppression and other characteristics, magnesium hydroxide is also widely favored by people because of its environmental protection and non-toxicity. Used in rubber, chemical, building materials, plastics, electronics, paint, paint and other industries.

1. Magnesium hydroxide flame retardant is cost-effective and can be added to polymers to achieve high loading.

2. The thermal decomposition temperature of magnesium hydroxide reaches 340 ℃, which is beneficial to increase the processing temperature of plastics, accelerate the extrusion speed, improve the plasticizing effect, shorten the molding time, and have high surface gloss, no surface defects, and ensure the super peel strength.

3. Magnesium oxide produced by the combustion and dehydration of magnesium hydroxide is a high-strength, high-heat-resistant material, which can be used as a protective wall to isolate fire sources and toxic and harmful gases. Magnesium hydroxide and acid have strong neutralization ability, which can quickly neutralize the acid gas generated during the combustion of plastics.

4. The physical form of magnesium hydroxide is granular, which is conducive to uniform distribution, good compatibility with the substrate, and has little effect on the mechanical properties of the product.

About the above content today to introduce so much, presumably we have a clear understanding, through the above described, we can see that magnesium hydroxide is a very ideal flame retardant, used in various industries. Zhongke flame retardant new materials inMagnesium hydroxideWe have rich experience in research and development and production in the surface modification of inorganic powders. If you have a need for flame retardants, you can call us at 0551-67712199, and someone will answer for you.

Real-time information

Zhongke Flame Retardant Organization Watches 20 Closing Ceremonies

As a flame retardant, magnesium hydroxide also need to improve what aspects?