How to improve the application effect of magnesium hydroxide flame retardant?

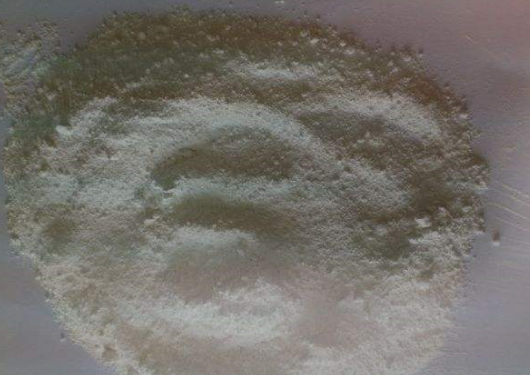

Everyone knows that flame retardants are still used in our lives and play an extremely important role. This includesMagnesium hydroxideAs a flame retardant, it is widely used in plastics and rubber products. Its mechanism of action is: release water through thermal decomposition, absorb a large amount of latent heat, reduce the surface temperature of the synthetic material filled in the flame, inhibit the decomposition of the polymer, and cool the surrounding combustible gas: Magnesium oxide Decomposition is a good refractory material, which helps to improve the flame retardant performance of synthetic materials, and water vapor can also be used as a smoke suppressant.

ImproveMagnesium hydroxideFlame retardant, smoke suppression, filling and other functions, it is important to make it have good compatibility with polymer polymers, and can be evenly dispersed in plastic and rubber systems. At present, the method used is to use a specific powder modifier to modify the surface of magnesium hydroxide, which can effectively reduce the surface energy of the powder, improve the shortcomings of strong polarity and easy agglomeration of the powder, and improve the compatibility of magnesium hydroxide and polymer.

I think everyone should understand the above clearly. Of course, in the current form, it appliesMagnesium hydroxideSurface modification additives mainly include surfactants (stearic acid, sodium stearate, etc.), coupling agents, etc. Various types of additives using different modification methods, including ultra-fine method, surface chemical coating and microcapsule modification methods, need to be explored according to the actual application needs to find a better production process.

Real-time information

Zhongke Flame Retardant Organization Watches 20 Closing Ceremonies

As a flame retardant, magnesium hydroxide also need to improve what aspects?