Factors of magnesium hydroxide as a flame retardant

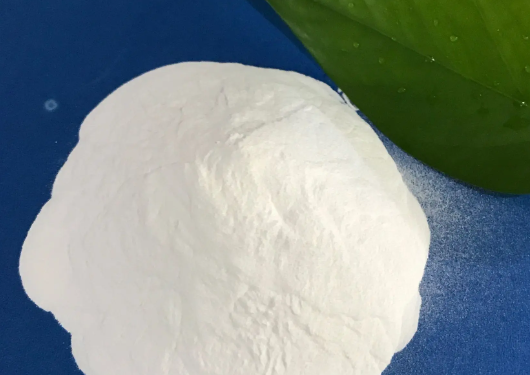

In order to prevent some flammable substances from being ignited, some flame retardant is usually added to flame retardant. Magnesium hydroxide is such an ideal flame retardant additive. This is inseparable from its own characteristics. The magnesium oxide produced by the combustion and dehydration of magnesium hydroxide has high strength and good heat resistance.Magnesium hydroxideAnd acid reaction can protect the fire source and harmful gases, resulting in no pollutants.

The particle size distribution is uniform, compatible with the substrate, and has little effect on its mechanical properties. Strong decomposition ability, high flame retardant efficiency, good smoke suppression ability; low hardness, low friction, and no damage to equipment. The high thermal decomposition temperature of magnesium hydroxide will also increase the plastic processing temperature and plastic efficiency. low cost,Magnesium hydroxideFlame retardants do not need to spend a lot of cost in actual production. Thus, these properties of magnesium hydroxide can make it an ideal flame retardant.

How to combine cost-effective ordinary flame retardants with slightly more expensive environmentally friendly flame retardants is not only an important topic that needs to be studied in many industries today, but also the future development direction of flame retardant products. While protecting people and property from fire threats, the potential hazards of flame retardants to humans and the environment should also be reduced. In fact, any chemical has its advantages and disadvantages for us. We should do a good job of how to seek advantages and avoid disadvantages. The key lies in scientific management and proper use.

At present, flame retardants are mainly divided into organic, inorganic, halogen and halogen-free four categories. Bromine flame retardants have certain advantages in organic flame retardant systems, but they have always aroused heated discussions among environmental experts.Magnesium hydroxideIn the halogen-free flame retardant system, red phosphorus can be called excellent effect, with the advantages of less addition, good flame retardant effect, wide application range and good environmental protection effect.

Real-time information

Zhongke Flame Retardant Organization Watches 20 Closing Ceremonies

As a flame retardant, magnesium hydroxide also need to improve what aspects?